Hardened steel is a key material in many industrial and structural applications. Let us now look in detail at its characteristics and the hardening process, which is essential for achieving the desired strength and durability.

What is steel hardening?

Tempering is a heat treatment that is performed on carbon steel to change some of its physical characteristics, particularly its hardness. Not all steels can be hardened; to undergo this process, steels must have a high carbon content or contain certain alloying elements that promote hardening.

History and evolution of steel hardening

- The tempering of steel represents a fascinating chapter in human history, a long journey of discovery and innovation that has shaped our modern world. Let us examine this journey through the ages:

- Iron Age: The origins of steel hardening date back to the Iron Age, when craftsmen and blacksmiths began experimenting with heating and cooling metals. This period marks the first empirical attempts to improve the properties of the metal, with the observation that heating followed by rapid cooling could increase the hardness of sword and knife blades.

- Antiquity: In ancient times, craftsmen refined empirical methods for hardening blades, involving heating the blades and cooling them rapidly in water or oil. These advances contributed to the production of increasingly effective weapons and tools.

- Middle Ages: During the medieval period, metalworking and heat treatments became even more sophisticated, becoming an integral part of the production of weapons, tools and implements. Craftsmen perfected tempering techniques to make stronger and more robust blades, contributing to the growth of manufacturing techniques.

- Industrial Revolution: With the advent of the Industrial Revolution, large-scale production required a deeper understanding of heat treatments. Scientists and engineers began to study the processes of austenitizing, cooling and martensitizing, introducing a new era of progress in metallurgy.

- 19th and 20th centuries: In the 19th and 20th centuries, scientific research and industrialization led to a greater understanding of metallurgy and heat treatment. Steel hardening became standard practice in many industries, including automotive, aerospace and manufacturing, revolutionizing production and helping to build safer and more efficient structures and machinery.

The Tempering Process: understanding the characteristics of hardened steel and the hardening process

The tempering process consists of three basic steps:

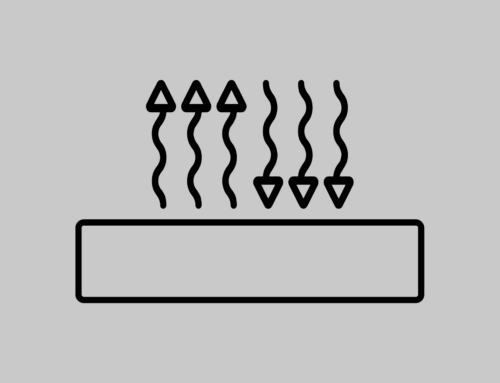

- Heating: steel is brought to high temperatures to change its internal structure. During this stage, the steel acquires the structure of austenite.

- Temperature maintenance (Austenization): steel is maintained at austenite temperature for a specific period. This step is crucial to ensure that the entire internal structure is completely transformed.

- Rapid cooling by quenching medium: steel is cooled rapidly by immersing it in a liquid or gas called “quenching medium.” This process transforms the steel structure into martensite, giving it hardness and strength.

Tempering Means

The main tempering media used are:

- Water: pure water is not recommended because it creates a vapor layer between the material to be cooled and the liquid itself, not allowing optimal cooling that may not allow the desired steel structure and hardness to be obtained. However, salt water (brine) is a better tempering medium.

- Mineral oils: mineral oils offer slower cooling, ideal in some cases. The resulting hardened steel is less brittle.

Final considerations

Tempering steel requires precision and care, especially for very thick sheets. After cooling, the artifact should be cleaned to remove impurities. Finally, hardened steel can be further heat-treated to reduce the internal stresses created by the hardening itself.

In conclusion, steel hardening is an essential process for obtaining strong and durable materials that are essential for industry and construction. For any technical inquiries or guidance on heat treatments and steel processing, feel free to contact Sidertaglio Lamiere. Our experienced technical and commercial team is here to support you in choosing the most suitable solutions for your specific needs.